SCG provides innovative solutions that are engineered and tailored to a client’s specific problem. In that process, we match products to applications to find the best and most cost effective solution. Advanced materials such as composite fabrics are often very effective alternatives for repair and rehabilitation work.

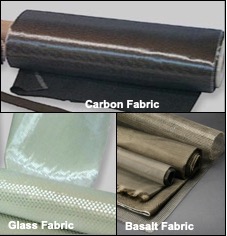

SCG works with the following materials (shown in order of highest tensile strength):

- Laminates – Carbon, basalt and glass for beam reinforcement, concrete crack repair and rebar replacement

- Carbon fabrics – for blast hardening and structural repair of concrete and/or steel infrastructure such as floor slabs, beams and columns, pipes and tanks

- Basalt fabrics – for structural repair where non-conductive material is required. Properties include no wicking and an insulator for temperature and sound

- Glass fabrics (both E-glass and S-glass) – used for axial confinement and applications requiring lower strength materials. Gas fabrics are also non-conductive.

Benefits:

Composite materials vary in tensile strength, insulating properties, installation procedures and cost. They all provide many benefits compared to traditional construction approaches including:

- Lightweight, easy to handle, can be inserted into confined areas

- East to install

- Corrosion resistant, long lasting

- Low overall costs compared to traditional concrete and steel methods

- High chemical resistance. Additional coatings can be applied as a topcoat for additional chemical protection

- Often materials can be installed while the process remains in-service

- High sustainability rating due to low energy needed to install and due to extended life-cycle of existing infrastructure