Project Highlights

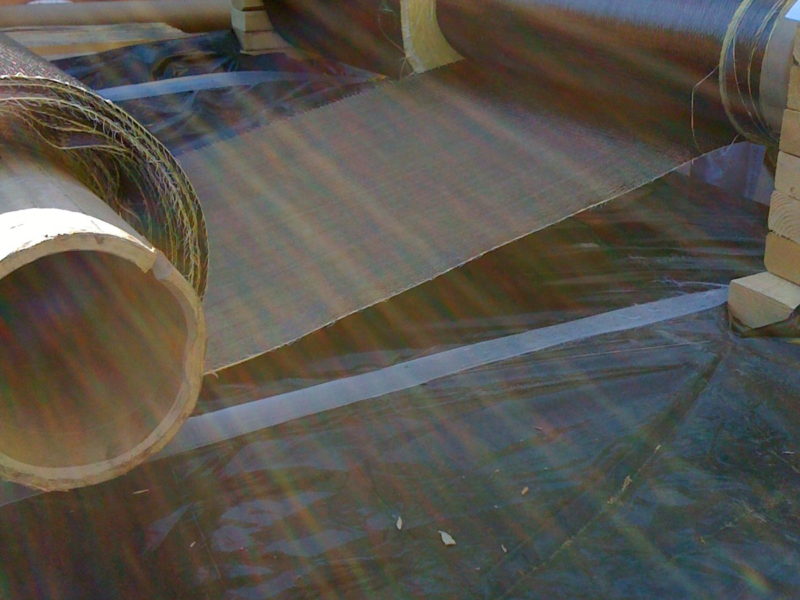

- Extended tank life – Reinforced external shell with lightweight composites

- Cleaned and lined upper 1/2 of tank interior

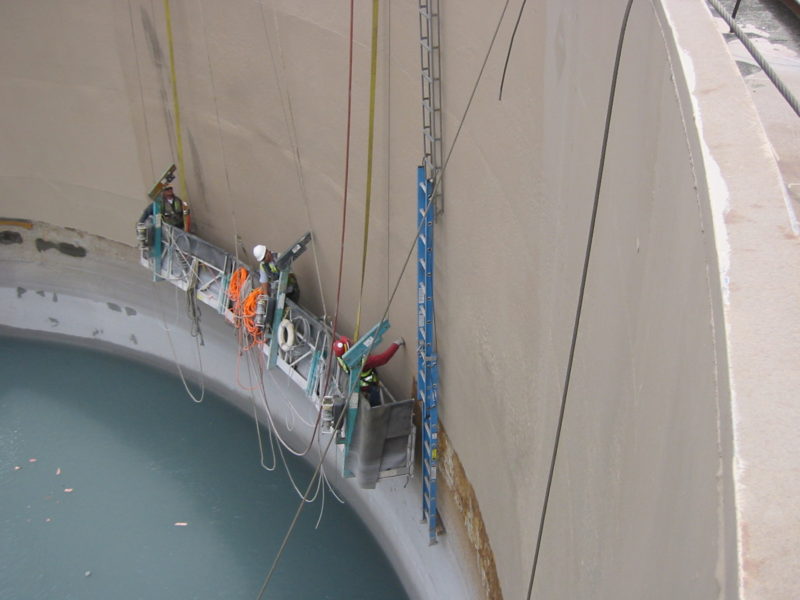

- No interruption – Project completed while tank was in-service

Project:

Restore structural strength and repair leaks to the 2.5 MG Process Water Tank. Clean and apply coatings to inside. Corrosion reduced steel thickness by up to 45% in upper portion of tank. Active leaks were difficult to repair due to thin steel. The tank is critical to mining operations and had to be repaired while kept in service.

Solution:

Installed carbon FRP to provide confinement and to restore structural integrity of the tank. Cleaned and removed corrosion inside and applied coating for protection.

Results:

Durable repair developed specifically for copper mines at a fraction of the cost of replacing the tank. No interruption to plant operations.